Times are changing in hot-rodding, there's no question about it. Classic Industries, recognizing the increase in the popularity of modern suspension and drivetrain parts in muscle cars and the high-caliber quality of parts now produced by the aftermarket, set out to build a heavily modified, modernized 1969 Camaro.

Times are changing in hot-rodding, there's no question about it. Classic Industries, recognizing the increase in the popularity of modern suspension and drivetrain parts in muscle cars and the high-caliber quality of parts now produced by the aftermarket, set out to build a heavily modified, modernized 1969 Camaro.

The end result was this, the Camotion 1969 Camaro.

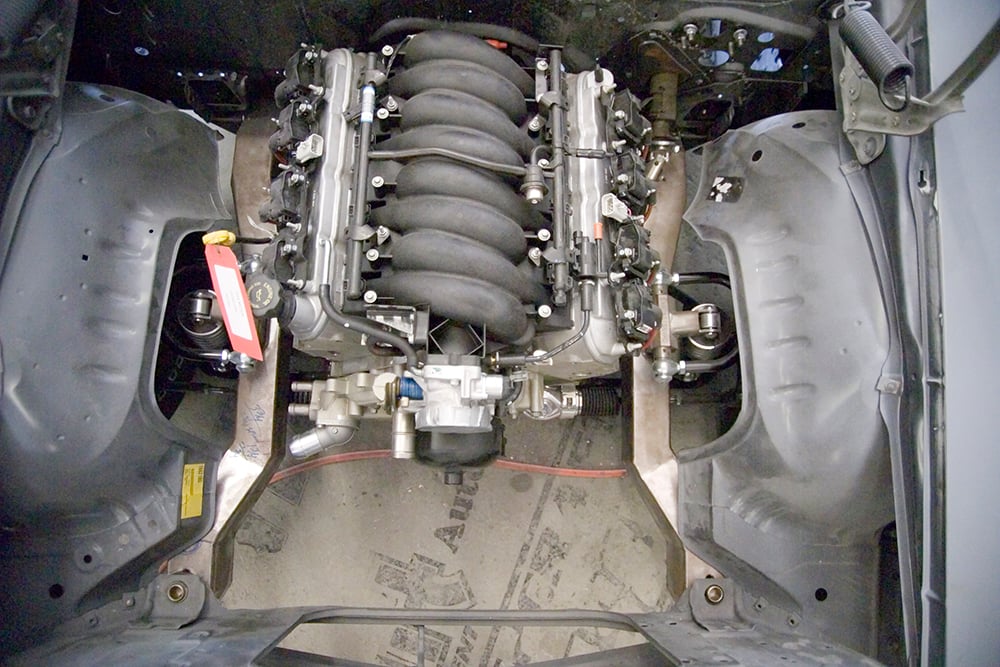

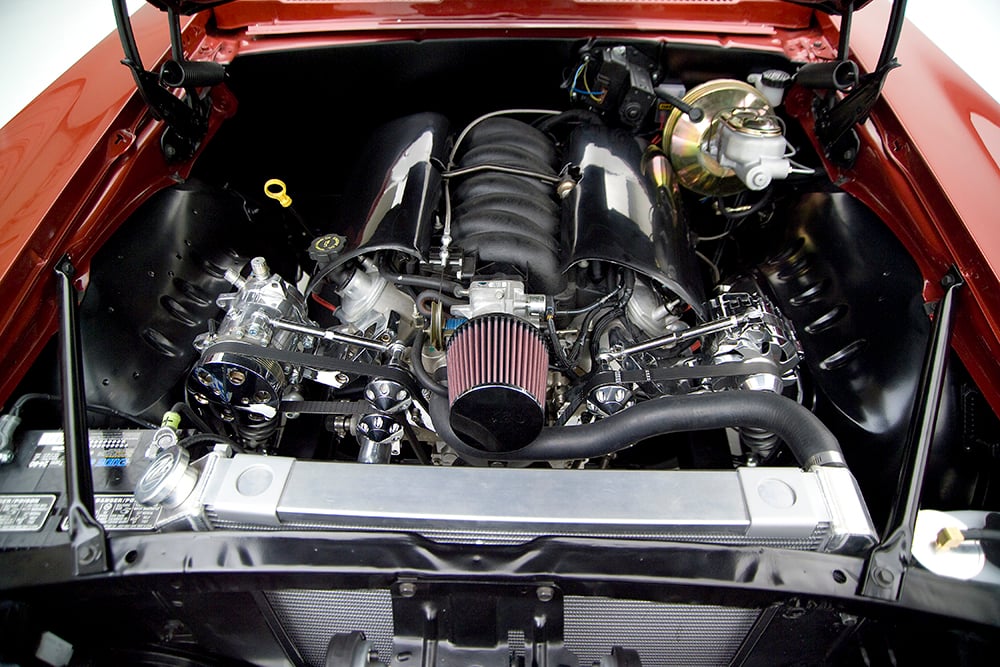

Our team started simply by bolting a LS1 engine to a Tremec T-56 transmission using a Keisler adapter kit. What we didn't know was that the project would take on a life of its own! Some of us here at Classic Industries really got involved in the project, researching parts and following leads to find just the right parts to make our modified '69 Camaro really haul. We mounted the LS1 using Art Morrison's LS1 mounting brackets (PN# AM325557), putting the engine and transmission in the perfect location, nestled into a performance front Subframe from Chris Alston's Chassisworks, featuring high performance VariShock coilovers. As the project got underway, word within the company spread like wildfire and before we knew it, every gearhead in the company had chimed in, throwing in their ideas into the ring. We took the best of everyone's input, giving the Camotion the spirit of the people here at Classic Industries.

Our team started simply by bolting a LS1 engine to a Tremec T-56 transmission using a Keisler adapter kit. What we didn't know was that the project would take on a life of its own! Some of us here at Classic Industries really got involved in the project, researching parts and following leads to find just the right parts to make our modified '69 Camaro really haul. We mounted the LS1 using Art Morrison's LS1 mounting brackets (PN# AM325557), putting the engine and transmission in the perfect location, nestled into a performance front Subframe from Chris Alston's Chassisworks, featuring high performance VariShock coilovers. As the project got underway, word within the company spread like wildfire and before we knew it, every gearhead in the company had chimed in, throwing in their ideas into the ring. We took the best of everyone's input, giving the Camotion the spirit of the people here at Classic Industries.

Next up in our build was Air Ride Technologies' 4-link rear suspension, however, we opted against running airbags and swapped in a set of Chris Alston's VariShock coilovers to match the VariShock coilovers already installed in the front Subframe. We chose to use Painless Wiring's LS1 Fuel Injection Management System to manage the LS1 at the heart of our Camaro. We found that the Painless Wiring system was true to its name and actually was "plug-and-play", making it much easier for us to get the modern LS1 powerplant up and running.

During our project, we got in touch with the guys at Street & Performance. They're great with details and during our build, they were able to supply us with many parts that even we couldn't find anywhere else. For our engine's accessories, we chose to use Street & Performance's serpentine belt system and also employed their LS1 headers. To keep our powerful hot-rod motor cool, we rustled up one of Be-Cool's high-capacity cooling systems with dual electric fans (PN# BC83168). With the BeCool system in place, we could be drag racing in Death Valley with the air conditioning on and we still wouldn't have to worry about overheating.

Word within the industry began to spread as we made calls about the project, and it didn't take long before our friends at Magnaflow heard about our project and jumped in too, bending up one of their stainless muscle car exhaust kits to fit around the Camotion's new 4-link rear suspension, giving the car the exhaust note that can really cause a commotion!

With our suspension sorted and engine in place, then it was time for the interior. Though here at Classic Industries, we provide complete reproduction upholstery and interior parts to restorers every day, on a highly customized build like the Camotion, we just couldn't leave the interior stock. We found that Scat's ProCar low back seats (PN# 815011 & 815012) gave us more lateral support than stock to keep us in the seat while cornering and what's better, they also give our seating the retro-modern look we were after. With the seats picked out, we then had a set of custom upholstery produced to match our retro hot rod's style. We didn't stop our interior makeover with just the upholstery, either. With our new LS1 under the hood, we needed a instrument cluster to make sure the driver always has the information they need. We got a hold of a custom instrument panel from John Covan's Thunder Road and stuffed it with AutoMeter Carbon Fiber-series gauges, creating a cluster that really keeps the driver informed with precise, racing-grade readouts of what the engine's doing.

The last we have to mention is bodywork. We only bring it up last just because dealing with reproduction body panels is what we do here every day. Starting with a shell with rusty floorpans with holes the size of Fred Flintstone's feet, we soon found that we were up to our necks in the ultimate quality control project. We found ourselves test fitting all kinds of sheet metal, making sure the OER® quarter panels (PN# 7779477 & 7779476), floor pans, fenders and braces all bolted up just the way they should. After all that, we can solidly say from firsthand experience that the fit of the products we offer is up-to-par. We'd like to take a moment to thank the gang at American Muscle Cars for their hard work helping to put the car back together and transform our shell of a '69 Camaro into the Camotion.

It's not every day that we get to build a car here at Classic Industries, though we help restorers build theirs every day. Through all the hard work and long hours, the staff here all had a great time with building the Camotion, and we learned a lot from experience. Ultimately, we hope that you, our customer, will benefit from the knowledge we gained building this car.

At Classic Industries, we believe that it is our number one priority to ensure that you will not only get the parts you need, but the information you need to install them and keep your project on the road. Whether it's sorting your way through the maze of harnesses of your electrical system, selecting the right accessory drive belt for your setup, choosing the right spring rate or eliminating the rust from the body of your project, Classic Industries has the experience to help you make the right purchases and the products you need to get the job done.